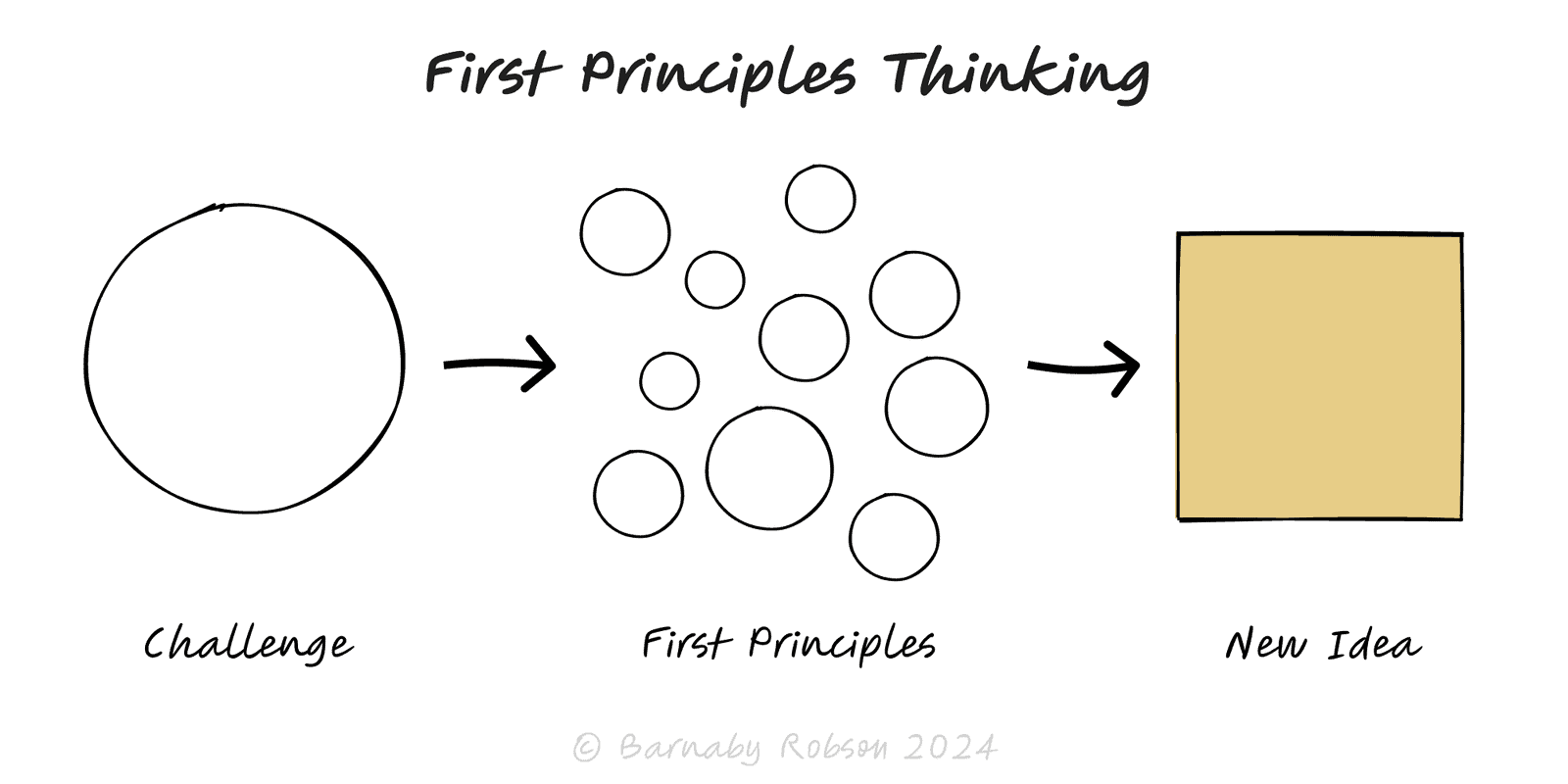

First Principles Thinking

Roots in classical philosophy (Aristotle); popularised in modern problem-solving by scientists and engineers (e.g., Feynman, Musk)

Most decisions are made by analogy (“do what worked before”). First principles thinking instead asks: What must be true? It separates hard constraints (physics, logic, maths, unit economics) from conventions (policies, legacy choices, supplier terms). By rebuilding from primitives, you uncover cheaper designs, new strategies and simpler processes that imitation would miss.

Deconstruct – break the problem into parts and claims.

Classify assumptions – mark each as a law, a measured fact, or a convention/guess.

Quantify primitives – core numbers (marginal cost, energy, latency, lead time, conversion) replace slogans.

Recompose – design options consistent with the hard truths, not with history.

Test & iterate – run small experiments; keep what matches reality, drop what doesn’t.

When to use analogy – only after first-principles to speed execution, not to cap imagination.

Strategy – rebuild the value chain; ask which activities are truly necessary and which are artefacts.

Product & pricing – set price from WTP and unit economics, not competitor lists.

Operations – zero-based process design; remove steps that don’t move the constraint.

Engineering – cost, weight, time, reliability redesigned from physical or computational limits.

Personal – goals, schedule and habits designed from outcomes, not inherited routines.

Define the job to be done – what outcome must exist, for whom, under what constraints (time, risk, budget)?

List assumptions – one per line; include “obvious” ones.

Sort them

Hard constraints (laws/identities): physics, arithmetic, legal non-negotiables.

Empirical facts: measured rates, costs, timings (with sources).

Conventions/opinions: policies, vendor norms, “we’ve always…”.

Translate to primitives – unit costs, cycle times, defect rates, energy, bytes, clicks, steps.

Design options from the primitives – at least three materially different approaches.

Model & compare – simple maths: contribution, throughput, latency, reliability; show breakpoints.

Run a cheap test – smallest experiment that could falsify your favourite option.

Decide & codify – choose, document new assumptions, set review triggers.

Reinventing the wheel – ignore existing knowledge and you burn time; scan prior art after step 4.

Hidden constraints – miss a real law (compliance, safety) and the design collapses.

Cargo-cult numbers – made-up inputs give false certainty; measure or bound with ranges.

Analysis paralysis – endless decomposition; timebox and bias to small experiments.

Social friction – challenging sacred cows threatens status; frame it as testing assumptions, not attacking people.